Lags

The DCMA allows a maximum of 5% of total task relationships to make use of a lag.

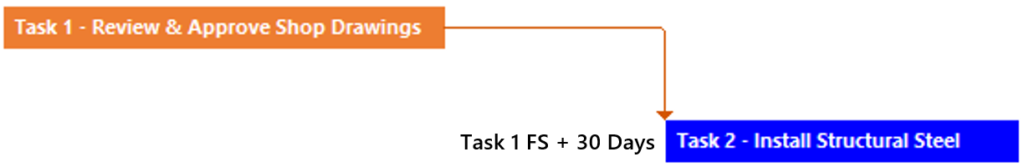

A Lag is a positive delay inserted between two activities in order to offset the start of the following activity. Lags are often used in a Finish–to–Start relationships such as the example shown below, where there is a 30-day manufacturing period between sign-off of Shop Drawings and install of Structural Steel which is handled by the insertion of a 30-day Lag.

Lags can be very confusing if the reason for them isn’t immediately clear, and whilst in an ideal world that reason should be recorded in the notes, very often it isn’t, so someone looking at the programme possibly months later could waste hours trying to figure out why. Add to this the fact that excessive use of Lags can cause obstructions to the critical path, and it becomes obvious why it’s recommended that they are avoided.

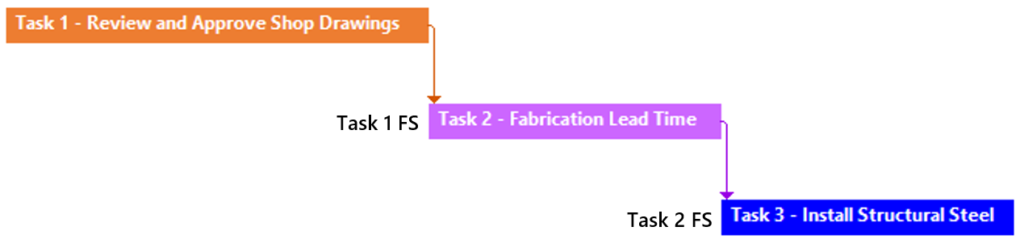

Generally, it’s better to use a specifically named task for clarity. In this case it would be far better and clearer to have a specific activity called fabrication time. Then if the activity slips to say 35 Days, it’s easy to see both cause and effect.

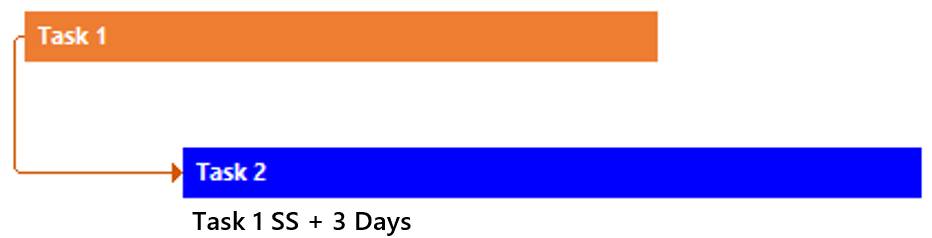

Lags are also often seen as a way to offset overlapping tasks in the same way that Leads were used in the previous section, illustrated by the overlapping Start–to–Start relationship below.

In the same way a Lead relationship can cause problems if there is delay on the first task; there is a similar risk on this type of relationship.

Although fixing the logic in this case is a little easier than the previous section, there is a potential for the first task to be left hanging with incomplete logic, which could affect calculation of critical path, and consequently care should be taken to ensure there are no gaps in the logic.